Silicone sponge, also called shut mobile silicone sponge or expanded silicone, is derived from a skinny sheet of uncured silicone gum that expands into a controlled thickness while curing within a high temperature push or rotocure operation. Closed cell means that the cells are non-interconnecting, hence they don't let drinking water to wick with the sponge.

When product designers or style providers are planning plastic products, it is possible to think about the subsequent details:

Thirdly, take into consideration the fabric supply and administration. Be certain that they can provide the plastic materials you require, and that these products are of good quality and are saved thoroughly.

In regards to the product structure, you ought to concentrate to if the thickness on the walls is even. Consider your very best to generate the variations in wall thickness as tiny as you can, to be able to stay away from complications like uneven cooling and the product getting deformed.

Just about the most popular silicone rubber products used in electronics manufacturing is wire harnesses. These are definitely bundles of wires and cables which can be employed to connect various parts within electronic products. Silicone rubber is a perfect content for wire harnesses

Closed mobile silicone sponges are available in tape rolls laminated with high quality adhesive backing. Stockwell Elastomerics inventories many NORSEAL silicone sponge goods in learn rolls with adhesive backings, then slits and cuts custom and standard gasket tapes for fast delivery. Silicone gasket tape is also known as a strip gasket or Strip-N-Adhere®.

Our facility is built to be the location’s premier prototyping and quick-run production facility with a wide array of high-precision tooling and equipment to meet any job.

During the early phase of improvement, start off-ups rely upon Initial Mildew’s custom plastic injection molding services to promptly turn product concepts into Bodily samples and flexibly reply to the industry with small-batch production.

We collaborate and customize all the things from The form and style to dimensions and format. Preliminary 3D renders may be found exact-week.

Elastic memory. Silicone extrusions attribute great elastic memory, making sure they're going to manage or return to their original shape right after publicity to high pressures or silicone parts manufacturing compressive forces.

Your input is evaluated swiftly and our structure is authorized. We get Performing instantly to supply and ship your purchase.

Thirdly, we should always integrate and simplify the look of parts. We could decrease the volume of parts by integrating many parts into one particular entire for injection molding.

In excess of fifty percent of the workers have above 10-yr industry practical experience for the right manufacturing of products.

ARCO® Silicone is listed here to assist with all your silicone manufacturing desires. We work with a wide array of superior-top quality products and may manufacture products to meet all of your demanded specifications. Speak to us to see how we are able to present you with customized methods for the exclusive software.

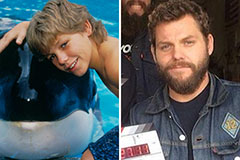

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now!